Liebherr’s Wind Turbine Breakthrough

Liebherr, a pioneer in wind turbine technology, is set to redefine industry standards with its latest innovation – a state-of-the-art main bearing test bench. This revolutionary test bench guarantees rigorous testing and validation of main bearings for offshore wind turbines, demonstrating Liebherr’s commitment to maximizing efficiency and reliability in clean, sustainable energy generation.

The Heart of Performance

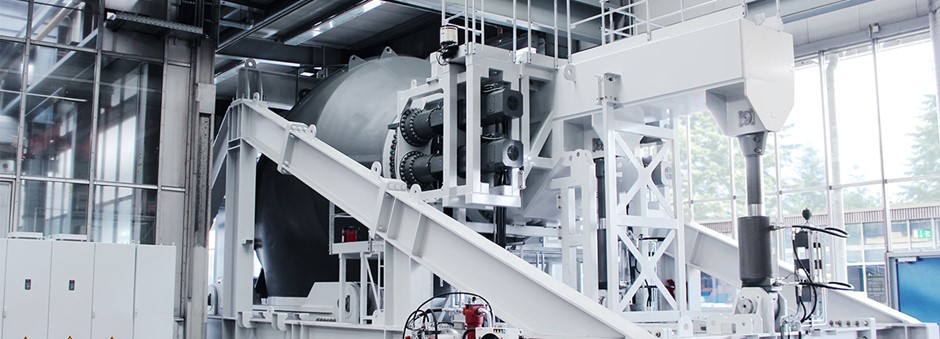

Main bearings serve as the heart of wind turbine rotors, playing a pivotal role in the overall system’s efficiency. To ensure these bearings meet demanding requirements, Liebherr-Components has constructed a cutting-edge main bearing test bench at its site in Biberach an der Riss, Germany.

The test bench performs a range of critical assessments, including functional testing of the bearing, inspection of the lubrication and sealing system, and measurement of bearing frictional torques under varying loads and operating conditions. Additionally, the test program involves determining the total bearing service life in specific operating conditions and analyzing the bearing heat balance at different operational points.

Testing the Limits

To execute these tests, two bearings are required – a test bearing and a counter bearing. Plate weights or hydraulic cylinders generate the test load, while an electric motor rotates the bearings. “To test a main bearing, we simulate the load it would experience over a six-month period. This involves subjecting the main bearing to overload conditions, mimicking the stresses it would endure throughout a 25-year lifespan,” explains Andreas Palmer.

Driven by Results

Inspections and tests not only validate main bearings but also uncover opportunities for further development. Andreas Palmer highlights the origin of their superfinish for main bearings as an example. The superfinish process refines the raceway surface, achieving an almost mirror-smooth finish through rotational machining.

Pioneering Progress

“Since 2015, Liebherr-Components has been supplying main bearings for wind turbines. With our new test bench, we can currently validate main bearings for an impressive 11 MW turbine,” summarizes Andreas Palmer. “This positions us optimally for the evolving market conditions and the continual growth of turbine sizes.”